Glycol, And Its Uses In Hydronic Systems

29 January

This blog looks at glycol, a dihydric alcohol commonly used within HVAC applications. But what exactly is it, what functionality does it have a valve system, and how do you use it? We’ll explore all of this and determine the best methods of use along with why we opt for glycol in HVAC systems.

Why Glycol?

We’ll be looking primarily at propylene glycol, which is less toxic than ethylene glycol (but both are classed as non-toxic), and is sourced from plants rather than fossil fuels, so is a great addition for environmentally friendly projects. As glycol has a lower freezing point than water, it is primarily used as an anti-freeze additive. This enables glycol to play a crucial role in preventing the freezing of water within HVAC systems, safeguarding valves, pipes, pumps, and other components from damage in colder climates. Glycol solutions also help prevent corrosion, protecting metal HVAC components and prolonging equipment life. When you add glycol to water, it can enhance heat transfer properties, although the ratio needs to be very precise, as too much glycol can actually reduce heat transfer efficiency.

Glycol is harmless to most materials, and indeed all materials used in FlowCon and FloControl valves, regardless if used on its own or mixed with water. However, it does alter the viscosity of the flow medium, making it seem “thicker”, thus leading to a slower flow. The concentration of glycol in the HVAC system will impact the pumping power, particularly at low pump pressures, where you may find flow issues due to a significant change in specific gravity.

Glycol Mix and the Flow Correction Factor

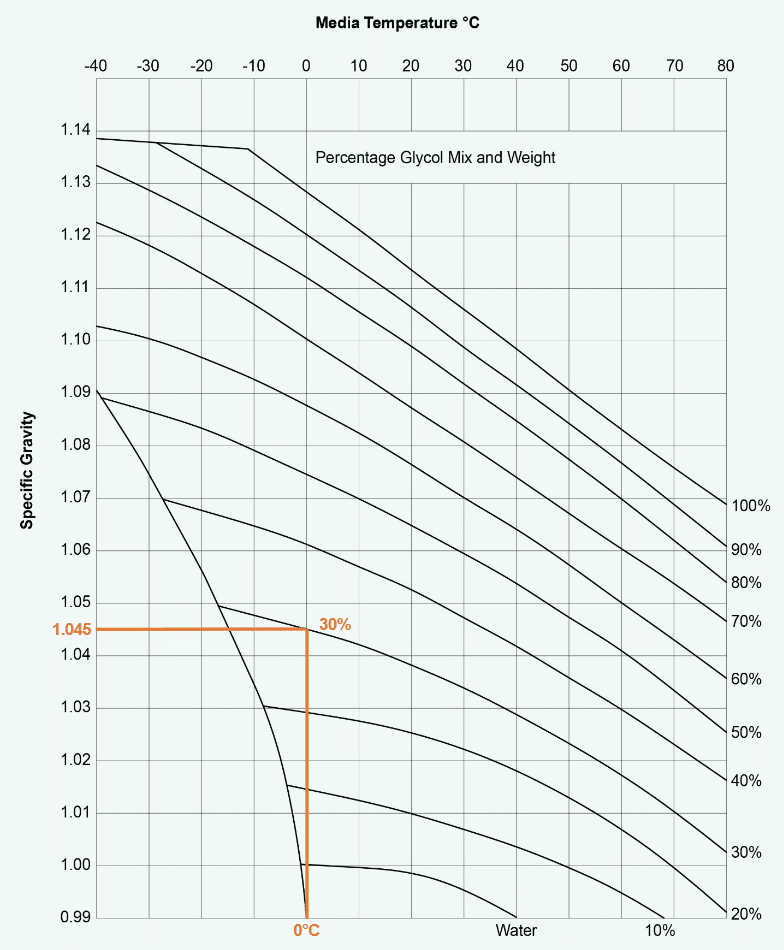

If you are using glycol, take a look at the graph below for an adequate flow correction factor. Such a factor should be based on media temperature and the percentage of glycol.

How to Read the Flow Correction Factor Graph:

What is the % of glycol? Select the curve corresponding to your selected water/glycol mixture. The percentage on the right-hand side of the chart refers to the concentration of glycol in the fluid, where 100% represents pure undiluted glycol.

1) % of Glycol: Choose the curve corresponding to the water/glycol mixture percentage.

2) Media Temperature in °C: On the top scale, find the appropriate media temperature and find the intersection with your glycol mix curve.

3) Flow Correction Factor: Draw a horizontal line from the intersection to the left axis to determine the specific gravity. This will correspond to the flow correction factor.

Glycol Mix Calculation Example

Let’s imagine a 0°C media, using a 30% glycol mix; this should provide a required flow of 2.7 l/sec. If we follow the graph instructions, you can see flow correction factor is determined to 1.045. This is indicated by the orange lines in the graph above.

For a Diaphragm Design, e.g. FlowCon Green.3 DN40/50, a flow rate of 2.7 l/sec would equal setting 3.2. But with 30% glycol at 0°C, setting should be adjusted. The required flow is multiplied with the flow correction factor → 2.7 x 1.045 = 2.82 l/sec. Consequently, the valve should be set to 3.35.

For a Moving Cup Design, e.g. FlowCon K DN40/50, a flow rate of 2.7 l/sec would equal a F3C2466 stainless steel insert providing 2.78 l/sec. The required flow is multiplied with the square root of the flow correction factor → 2.7 x √1.045 = 2.76 l/sec. In this case the F3C2466 insert will still be the valid choice.

Need more Information? Contact us for more information or help in how to determine your flow correction factor or explore our FloControl products to familiarise yourself with our range.